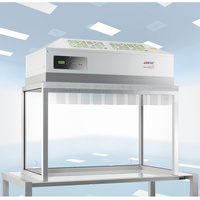

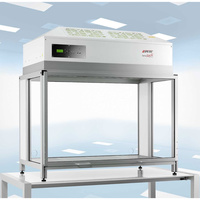

Spetec Portable tabletop exhaust hood EBS series

Exhaust hood without filter module

The portable tabletop exhaust hood EBS is universally usable. It is corrosion and acid resistant. The maximum extraction capacity is 1 cubic meter per minute and is continuously adjustable.

|

Width:

|

701 mm - 800 mm1001 mm - 1100 mm1301 mm - 1400 mm1601 mm - 1700 mm1901 mm - 2000 mm

|

|

Device type:

|

fume hoodclean benchProduct protection

|

|

Height:

|

901 mm - 1000 mm

|

|

Cleanroom equipment:

|

Laminar flow box

|

|

Depth:

|

701 mm - 800 mm

|

| Protection box |

Spetec PBS series |

| Type/Size |

PBS 37 |

PBS 56 |

PBS 75 |

PBS 93 |

PBS 112 |

| Interior height (mm) |

805 |

805 |

805 |

805 |

805 |

| Height with the open door (mm) |

1441 |

1441 |

1441 |

1441 |

1441 |

Outer dimensions

W x D x H (mm) |

735 x 793.3 x 940

|

735 x 793.3 x 940

|

735 x 793.3 x 940

|

735 x 793.3 x 940

|

735 x 793.3 x 940

|

Spetec Clean room technology Service

We - as a manufacturer and service provider for clean room technology - provide a range of device variants on the one hand, and fast and universal service assistance on the other hand. Now we have used our many years of experience as a manufacturer to develop a services offering, which allows us to test, service, and maintain your clean room system using state of the art measuring equipment.

Very clean air is not just vital in clinic operating rooms. Highly sensitive production environments, such as those in the semiconductor production, precision engineering, optics and optoelectronics, laser technology, or food processing industries, also demand a sufficient level of ambient air quality. In order to ensure this, flow velocity or filter tests are required at regular intervals.

We offer the following services:

- Particle counts

- Replacing filters in various brands of laminar flow boxes (LF units)

- Finding and fixing leaks

- Determining volume flow rates or flow velocities

- Temperature and relative humidity measurements

-HEPA filter / filter system installation monitoring

- DEHS leak test

- Clean room validation and certification in accordance with EN ISO 14644 and GMP guidelines

We also perform certification within the framework of EN ISO 14644, that is, we record the measurement parameters defined in DIN EN ISO 14644 such as particle counts, flow velocities, etc. All of these parameters are confirmed with a corresponding certificate.

All of the particle measurement devices, air speed, temperature, and humidity sensors we use are tested and calibrated every 12 months.

Our offering includes service and maintenance work as well as certification of clean rooms and laminar flow boxes according to the current national and international guidelines and standards. These include the VDI 2083 and DIN EN ISO 14644 guidelines as well as the US Fed Std. 209E. You receive comprehensive documentation about the measurements and a risk assessment.

Catalog Clean room technology

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details