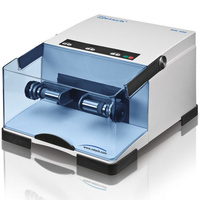

FRITSCH PULVERISETTE 0 Vibratory Micro MillThe grinding in Ball Mills takes place through impact and friction of the sample between grinding balls and the inside wall of the grinding bowl respectively the mortar. FRITSCH Ball Mills grind dry or wet medium-hard to hard samples to finest fineness. Also ideal for mixing and perfect homogenising.

Vibratory Micro Mill PULVERISETTE 0: For fine comminution of dry laboratory samples or solids in suspension. For homogenisation of emulsions or pastes. The device is recommended for sample preparation of RoHS tests (Restriction of Hazardous Substances).

Method of operationThe FRITSCH Vibratory Micro Mill PULVERISETTE 0 grinds your sample through impact and friction by which the mortar vibrates electromagnetically and the grinding material transfers the vibrations to the grinding ball. At the beginning of the grinding, the comminution of the coarse particles is achieved by the impact effect of the grinding ball. Next, the fine particles are comminuted through friction by the tumbling motion of the grinding ball as the vibrations subside. The impact energy of the grinding ball is freely adjustable thus, allowing it to be precisely adapted to the sample being ground.

Features

- Effective comminution in a narrow, homogeneous particle size range

- Loss-free grinding in a closed vessel - dry or in suspension

- Cryogenic grinding and simple embrittling in the cryo-box

- Modular system for simple conversion to dry or wet sieving

- Adjustable oscillation amplitude for easy adaption of the vibration energy to the grinding sample

- Grinding and sieving in one unit

- Agglomeration phenomena avoided

- Ergonomically positioned membrane keyboard IP65, splash-proofed

- Recyclable plastic housing

- Convertible for cryogenic grinding

- Window for observing the grinding progress

- Digital timer

- Standard equipment includes grinding head (included in price)

- Mortars and grinding balls in 6 different materials, all mortars are rimmed in an aluminium shell.

Equipment

The grinding lid is included in the standard equipment delivered with the Vibratory Micro Mill (included in the price of the instrument). Mortars and grinding balls are offered in 6 different materials and must be ordered as accessories. The PULVERISETTE 0 can also be converted to a Vibratory Sieve Shaker ANALYSETTE 3 SPARTAN for dry and wet sieving.

Suitable for the following material samplesmedium-hard, brittle, temperature-sensitive, moist

Please note: For this FRITSCH mill, you require a mortar and one grinding ball. The mortar material must also be harder than the material to be ground. In normal cases, a mortar and ball of the same material are used. For cryogenic grinding, please use mortars and grinding balls of steel or tungsten carbide.

The PULVERISETTE 0 can also be converted to a Vibratory Sieve Shaker ANALYSETTE 3 SPARTAN for dry and wet sieving.

|

Mills Appliance type:

|

ball mill

|

|

Process type:

|

batch

|

| Shipping weight: |

22,00 Kg |

| Product weight: |

21,00 Kg |

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details