FRITSCH PULVERISETTE 25 Power Cutting MillCutting mills comminute the sample by cutting and shearing forces. They are ideal for comminution of soft to medium-hard, fibrous and tough materials, plastics and heterogeneous mixtures. The FRITSCH-Plus: unbeatable quick and easy cleaning - all grinding parts can be removed in a few seconds without tools.

Power Cutting Mill PULVERISETTE 25: For pre-crushing of dry, soft to medium-hard or fibrous materials and plastics. Max. feed size: 120 x 85 mm

Areas of applicationFor the preliminary comminution of plastics, rubber, films, leather, fabrics, fibres, wood, leaves, roots, animal fodder, grain, corn, peat, tobacco paper, cardboard, derived fuels, metal-free waste, household waste, composites, LCD glass and keypads of mobile phones, electronic chips, circuit boards (populated and unpopulated), coal, bones, horn, dragées, tablets, cork, drugs, derived fuels, heterogeneous mixture of materials, maize, malt, pasta, herbs, spices, dried meat and straw - which can be fed at full length.

In addition, the Power Cutting Mill can also be used in the pharmaceutical or animal feed industries, in dental, medical and metallurgy technology, at veterinary institutes and for RoHS testing.

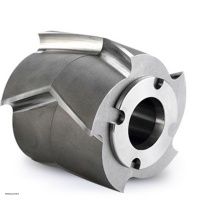

Method of operationIn the grinding chamber of the Power Cutting Mill, a rotor fitted with knives comminutes the grinding sample in combination with three fixed knives at low rotation speeds.

Features overview

- Fast, reproducible comminution thanks to the high-torque gear motor (2.2 kW)

- Different rotors for adapting the cutting performance to the sample

- Cutting rotor and sieve cassette can be removed and replaced without tools

- Cutting gap can be adjusted externally

- Housing and cover open up completely

- Easy, fast and thorough cleaning of the grinding chamber and all grinding parts

- Certified safety (CE mark) and 2-year warranty

Equipment

Required accessories for the Power Cutting Mill PULVERISETTE 25 can be ordered according to your demands:

Standard funnel for bulk solids, 10 litres or protected funnel with sample pusher, 3 litres

Standard rotor with V-cutting edges and fixed knives made of tool steel, hardmetal tungsten carbide or chromium-free tool steel or disk milling cutter rotor with indexable inserts and fixed knives made of hardmetal tungsten carbide

Sieve inserts with trapezoidal or square perforation in stainless steel 316 or chromium-free steel ST12

Collecting vessel, 3 litres, or collecting vessel for large quantities, 10 litres

An universal support stand is optional

Suitable for the following material samplesmedium-hard, brittle, tough, fibrous samples

Please note: For this FRITSCH mill, you require a feed funnel, a cutting tool set, at least one sieve cassette and a collecting vessel.

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details

Details